3D printing – now everyone can do it!

These days, technology develops so fast, however the speed and the turnover of it all is not dazzling.

In light of all those developments, the world has been finally exposed to three-dimensional printers.

Many still fear them. They even feel like they are taboo!

Our goal in this post is to refute this way of thinking and to make 3D printers available for you too. And how knows?

Maybe in the process we could even teach you something new.

So let’s start by explaining how this printer became a significant part in our lives, and accessible to each and every one of you.

A bit of history could never hurt…

The first 3D-Printer was created in 1983 by Chuck Hull from “3D systems corporation” a manufacturer of three-dimensional printers.

In 1987, “Cubital” was established under the “Scitex Corporation” in Herzliya Pituach,

which dealt with a method of construction in layers.

As it turns out, 3D printers are actually old news!

Wouldn`t you like to know how it works?

It works much like our familiar 2D home printer, but the ink has been replaced with different materials.

This material contains a type of glue that will bond the layers of the model.

The printer prints three-dimensional height, created layer after layer.

To support the construction, there are programs that add layers used as support from a softer material,

which are removed from the model at the end of the printing process.

So what is being printed today?

Today there is a wide variety of 3D printers; industrial printers for production of metals,

printers capable of printing colorful objects, and even home printers at relatively low prices.

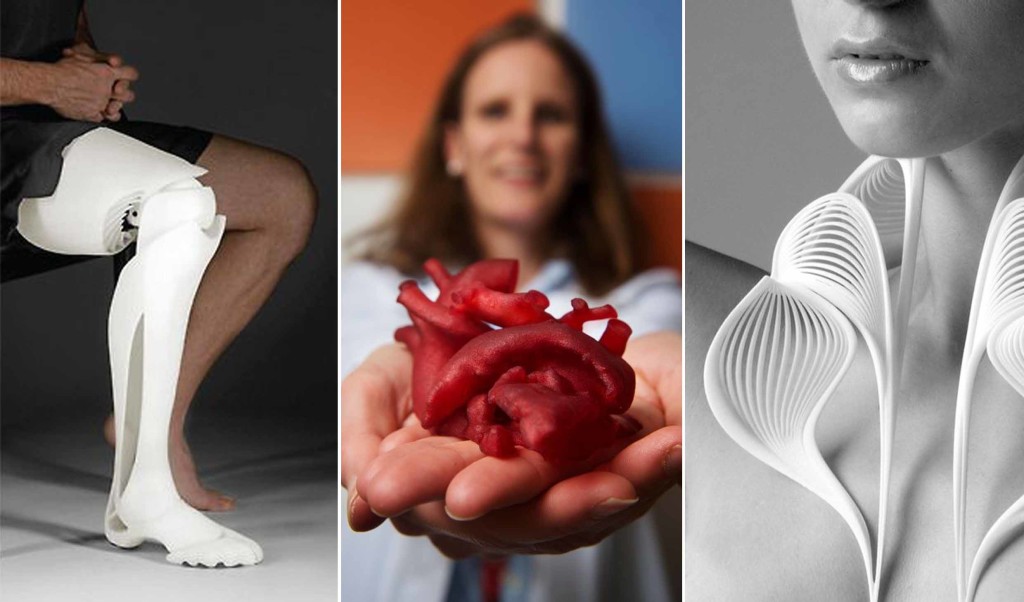

3D Printers are used in industry for the production of models, complex metal parts, ceramics, jewelry, fashion and more.

There are also attempts to manufacture printers for food production, buildings, body parts and many other interesting things.

Here are some cool examples:

What are the benefits of the 3D-printer, you ask?

One of the printer’s main advantages is the fact that some models simply can`t be produced by any other technology.

Manufacturing complex and richly ornamented items doesn`t require more time.

Production of different shapes and one-piece items.

Also, both complexity and simplicity in three-dimensional printing have the same price.

Of course there are many other benefits, such as:

Reducing assembly work which shortens the supply chain, saving manpower, transportation and the costs involved.

The shortening of the supply chain will in turn reduce air pollution. And who doesn`t like nature?

The 3D-Printer virtually eliminates all barriers and opens up a new and huge world of design possibilities.

This printer can create shapes that were previously made only by Mother Nature herself.

The design space has become infinite!

Like to print?

Here is what you need: an extremely talented product designer, three-dimensional files

from a 3D software (SolidWorks / Rhino / DMAX3) and a printer.

Sounds simple, doesn`t it?

We suggest you work with professional and trained product designers – it is important

that you get appropriate and accurate solutions to your requests.

If you haven`t found a talented designer, there are existing platforms and collaborative websites,

from which you can buy or download free files for 3D products.

After you have the file in your hands, there are businesses across the country

that can print it for you (We’re working with some of the best, if anyone is in need of a tip).

Where the printer fits into our work? Preparation of prototypes!

If you recall, in our first article we`ve talked about our development process

For those of you who didn`t got the chance to read:

The Product development process includes modeling to examine the feasibility of a product.

Three-dimensional printing technology makes it possible to create models that are easily affordable.

Here’s an example for one of our development processes:

A month ago we created for a client a mid-stage model aimed to demonstrate proportions,

ergonomics, the connection of pieces, use scenario and more.

In fact, the idea is to create a model as close to reality as possible, to save our client money and precious time.

In conclusion,

It is important to know that each type of printing has its advantages and disadvantages.

It is important to know and understand what fits your needs.

If you want to be exposed to this technology and to understand what your needs are,

you should consult with a reliable professional in the field. Otherwise, you might end up spending

more money and energy than necessary.

For further questions, contact us by e-mail directly at: studiordd@gmail.com

We are more than happy to help.

See you next time,

Ilana and Alex – Studio RDD

Leave a Reply

You must be logged in to post a comment.