“make me a few quick sketches”

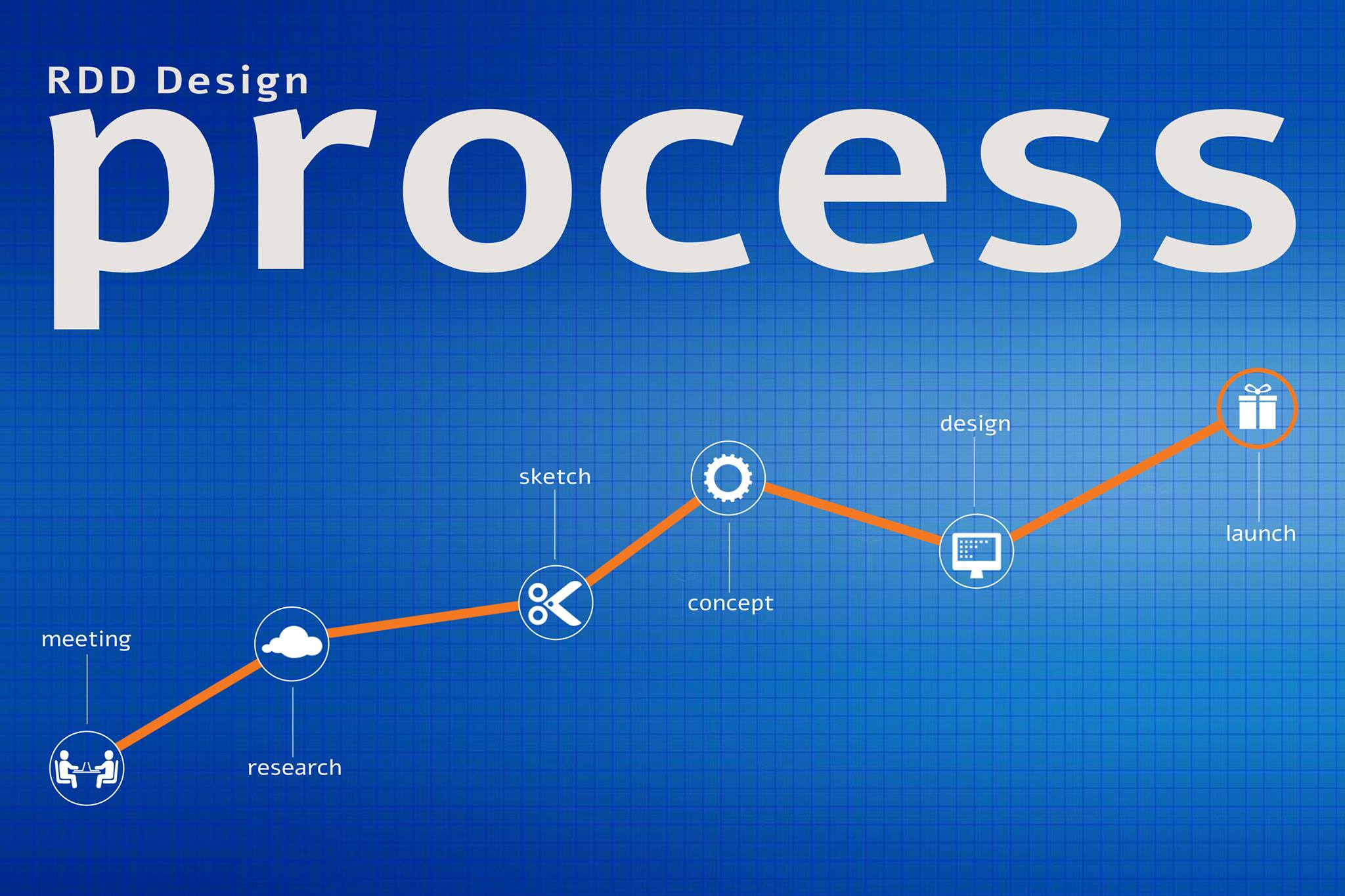

How many times have you heard the phrase “make me a few quick sketches”? We are here to tell you how this process really works, from the primary idea up to the final product ready to be delivered.

After all, you want to grant your customers the best merchandise possible.

There are 4 main steps in product development which helps us to exam every single obstacle and aspect along the process, those steps are a great influence on the final cost and value of the product. To make this information clear, we choose to tell you only the main steps of the process, however we promise that in the future we will expand and analyze each and every one of them.

Stage 01 – Research and analyze

The first step in the process is to analyze the client characterization, understanding the corporation agenda and the existing market. This stage demands a deep familiarity with the competitive products, relevant materials, new technologies and target customer understanding. At this stage we can understand how to make a product the right solution for the company that needs it.

Stage 02 – Concept development

Now with all the collected data, you are ready to develop the concept for the initial idea. This step basically offers the client a few solutions for the same problem, when each and every one of them is made of different materials, with different mechanics and design (we work with 3 different options system, which you will hear all about them, next time). From all the presented options, the customer chooses only the one he liked the most. From there the concept continues to the advanced development.

Step 03 – Prototype

The main purpose of this step is to create a prototype as similar as possible to the final product. Why do we need it? No matter how good your imagination and technical skills are, there is always a gap between sketches and illustrations to the real deal and to be able to close this gap, the designers and the clients must see and feel the prototype to make sure there are no mistakes. It’s important to remember that usually at this point you discover a few things that needs to be changed or repaired before you proceed to the final product.

Step 04 – Manufacturing

The preparation and the manufacturing step includes many sub steps, depending on the product and it`s materials. To do this stage properly we will need a few important things: – 3D files of the final product parts. – Product drawings, measurments, illustrations and 3D prototype. – Understanding the process steps and parts assembly In addition: Professionals, suppliers and molds.

In conclusion, it’s crucial to understand that this process demands time and resources, it’s absolutely important to do all the steps above correctly, in the right order, with no steps left behind. If you miss only one them, your product will probably fail.

Those millstones are well known as the methodological technic that helps taking a good idea and making it a great product, manufactured in mass production. In addition, it’s important to remember that even though it looks like a systematic process, to make a product you need to be very dynamic and flexible due to outside variable elements.

We hope you enjoyed reading this text and we will be glad to hear about your working processes.

Leave a Reply

You must be logged in to post a comment.

[…] https://www.studio-rdd.com/posts/how-many-times-have-you-heard-the-phrase-make-me-a-few-quick-sketche… […]